Measuring Nozzles with X-Ray Tomography

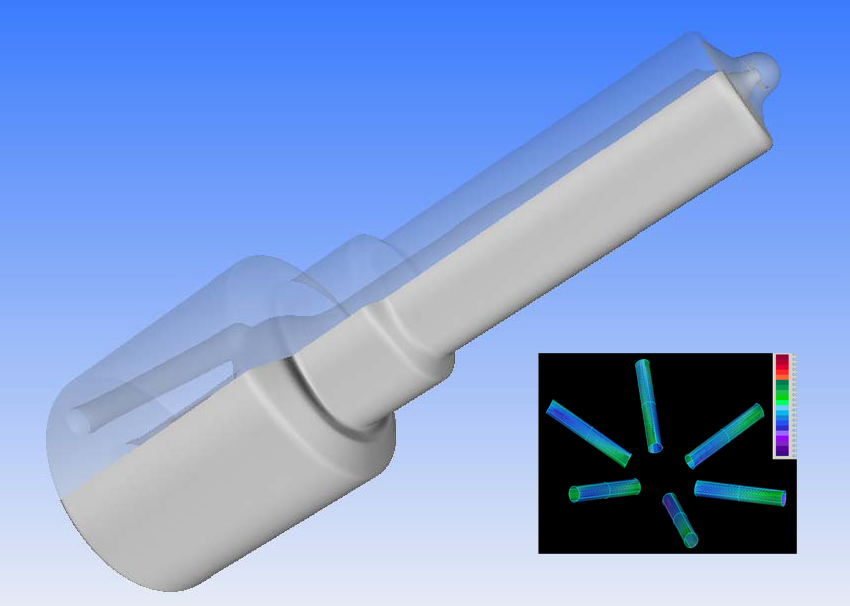

Measuring fuel injector nozzles has been part of the standard repertoire at Werth Messtechnik GmbH for over 10 years. Typically, the injector hole diameters of just a few tenths of a millimeter are measured using VideoCheck® multisensor coordinate measuring machines with rotary/tilt axes and the Werth Fiber Probe. Nearly all manufacturers around the world today of injection systems for gasoline and diesel engines use this technology, patented by Werth. The first TomoScope® for this measurement task has been in use for several months. One significant advantage over the fiber probe is the shorter measurement time for a significantly higher number of measurement points. Areas in the interior of the nozzle that are difficult to access can be measured easily using tomography. The wall thickness and pressure-side volume can be determined completely and non-destructively in a single setup without false castings. Fixturing is also less expensive, because difficult to access datum points can now be measured directly and need not to be defined by the fixture.

X-ray tomography provides very good reproducibility. However, due to artifacts typical of the process, for example, beam hardening and scattered radiation, the “absolute precision” is not sufficient for measuring injector holes with tolerances of a few micrometers without additional measures. The low measurement deviations required, in the sub-micrometer range, are achieved by the patent-pending Werth AutoCorrection process.

The new Werth Nozzle Module, developed from years of experience, has greatly simplified the measurement. Complete parameterization allows measurement of a large number of different types of nozzles without any user programming. With just a few entries, measurement and analysis of diesel and gasoline injector nozzles are performed automatically. This software solution can be used with the full range of VideoCheck® machines with image processing and fiber probe, or TomoScope® machines with X-ray tomography sensors. This ensures that measurement results from different Werth technologies will be comparable.